Brief Description

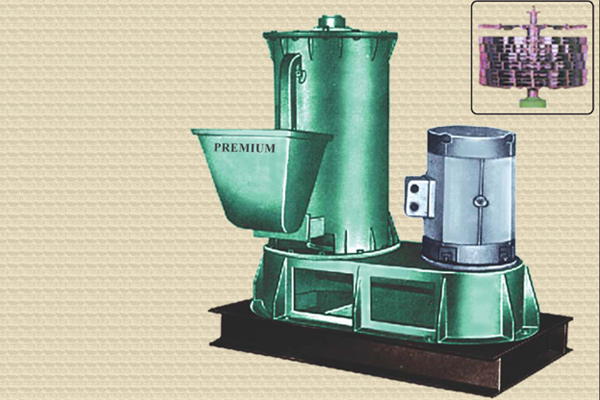

The EHIRPUL MICRONIZER unit consist essentially of an assembly of multi - chambered rotor units interpolated with circular discs and mounted on a shaft which rotates insides a casing lined alloy steel liner plates. A lower and upper fan cause an air current to circulate through the annular space between the rotor and stator, the quantity of which is regulated by means of air slides.

The material to be pulverised is fed into the base of the WHIRLPUL MICRONIZER unit, and is introduced in an intensely turbulent and upward moving air current until it reaches the upper section of the unit.

A re-Cycling duct ensure that any insufficiently ground material can be re-introduced into the lower section. The complete installation also includes a cyclone for the collection of finely ground material and a Dust Collector.

Working Principle

The distinctive principle of WHIRLPUL MICRONIZER equipment consist of introducing the material to be pulverised into an air current and thereafter submitting it to :

(a) Intense Turbulence: (b) Change of pressure : (c) Vibration:

Which progressively disintegrate the material or cause it to shatter from within (as in the case of cellular matter).

These conditions arise at the periphery of the multi-chambered had to be traversed by the air current carrying the material.

The WHIRLPUL MICRONIZER is based on the principle of circulating the product to be ground within an air system. The product is progressively micronised at the periphery of the rotors under the effect of blades shock, lining relief and attrition.

Principle Application

(A) Plastic Materials and Synthetic resins (vinyl.).

(B) Heat sensitive chemical products, elastomers.

(C) Non-metallic minerals (clay, Limestone and dolomite, graphite, coal, diamaceos earths, mica, Sulphur, etc....)

(D) All chemical compound in a solid state (metallic, salts, organics, catalytic materials etc....)

(E) Pigments and Dyestuffs.

(F) Insecticides (HCH & DDT with their carriers).

(G) Gums

(H) Cereals and other milling products.

(I) Animal feeding stuffs and other vagetable products.

Technical Specifications

| MODEL | H.P. | ROTOR DIA. (M.M.) | CAPACITY PER HR |

| PWPM – 350 | 5 – 15 | 350 | 10 KG. |

| PWPM –500 | 25 –50 | 500 | 30 KG. |

| PWPM –750 | 75 –100 | 750 | 90 KG. |

| PWPM –1000 | 120 –150 | 1000 | 200 KG. |

| PWPM –1100 | 150 –180 | 1100 | 300 KG. |

Remarks

Capacity Based on GUAR (Grains) for approx. 150 mesh.

Actual trial can be conducted in our Demonstration Room

Note : (1) THE CAPACITY DEPENDS ON SIZE, DRYNESS, GRIND ABILITY AND REQUIRED PRODUCT FINENESS OF MATERIAL FED. ( 2) DRIVE HORSE POWER CONSUMED WILL DEPEND ON DUTY CONDITION. ( 3) SPECIFICATION AND DESIGN ARE SUBJECT TO CHANGE WITHOUT NOTICE FOR ANY ADDITIONAL IMPROVEMENT

Whirlpul Micronizer Popular Applications

| Algae | Casein | Clays | Legumes | Polyamide | Sulpher |

| Antibiotics | Cellulose | Coal | Lime | Polyethylin | Synthetic Rubber |

| Aqua Feed | derivativer | Cocoa | Maige | Poultry feed | Titanisum oxide |

| Calcium Carbonate | Ceramic materials | Colloids | Metallic oxide | Protien | Urea |

| caolin | Cereals | Dyestuff | Metallic Salt | PTFE | Vermicide |

| carbide | Chalk | Glass | Millet | PVC | WAX |

| Carbohytrates | Chlorides | Guar gum | Peat | Serpenline | Zirconium |

| Carbon Black | Chocolate | Gypsom | Pectin | Soja | |

| Carbonates | Chrom oxide | Koolin | Pesticide | Spices |