HAMMER CRUSHER

Premium Hammer Crusher Is Designed To Disintegrate Materials In Small Pieces. Big And Rregular Size Of Feed Stock Are Ground Into Small Sizes To Facilitate Movement And Further Grinding.The Grinding Elements Rotate Against Grinding (Serrated) Plate And Material Is Cut Into Small Pieces. Generally Large Hole Size Perforated Screen Is Put Inlower Part Of Crusher Decides The Size Of Ground Material This Is Advanced Version Of Traditional Disintegrator Who Are Having Nx Grinding Rods. Premium Hammer Cr8shers Ae Having Swingif/G T/@ Ijamiger Bars. The Shape Ard Size 0f Hammers Is Designed To Suit The Application. Hammer T/Pe,Serratiofls Of Grinding Breaker) Plate, Speeo Of Rotor And Size Of Scredi Hole Decides The See Of Endpr0dij¢F.This Crusher Is Ldealforflbr0ljs, Bijliff, Irregular Shapeo Materials Into Coarse Sizemderial.

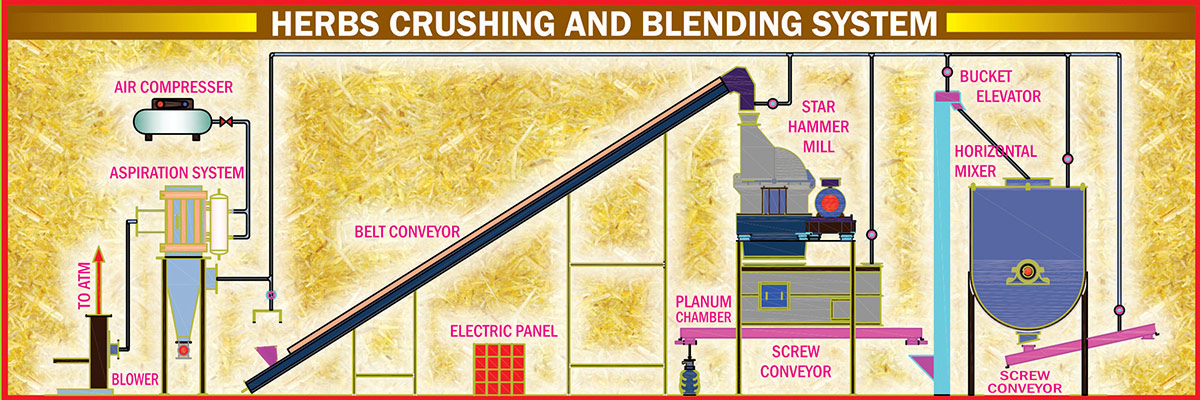

MIRACLE MILL(STAR HAMMER MILL)

MICRO PULVERISER

IMPACT PULVERISER

WHIRLPUL PULVERISER

The WHIRPUL MICRONIZER Unit Consist Essentially Of An Assembly Of Multi – Chambered Rotor Units Interpolated With Circular Discs And Mounted On A Shaft Which Rotates I Insides A Casing Lined Alloy Steel Liner Plates. A Lower And Upper Fan Cause An Air Current To Circulate Through The Annular Space Between The Rotor And Stator, The Quantity Of Which Is Regulated By Means Of Air Slides. The Material To Be Pulverised Is Fed Into The Base Of The

WHIRLPUL MICRONIZER unit, and is introduced in an intensely turbulent and upward moving air cunent until it reaches the upper section of the unit. A re-Cycling duct ensure that any insufficiently ground material can be re-introduced into the lower section. The complete installation also includes a cyclone for the collection of finely ground material and a

HORIZONTAL MIXER

VIBRO SCREEN

REVERSE PULSE AIRJET DUST COLLECTOR

BUCKET ELEVATOR

BELT CONVEYOR

SCREW CONVEYOR