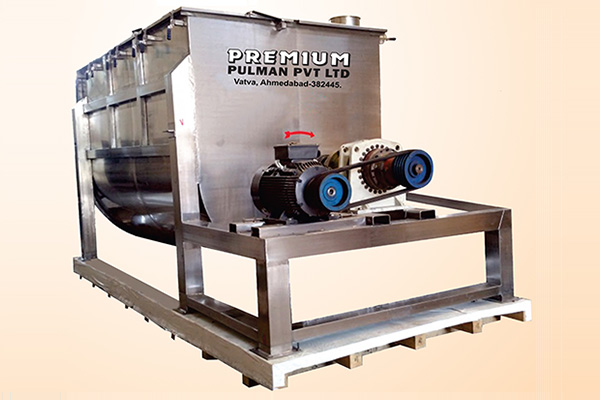

HORIZONTAL MIXER (BATCH TYPE RIBBON BLENDER)

SPECIAL FEATURES

- Most suitable for mixing cattle and poultry feeds. Produces a homogeneous mix in dry or wet condition.

- Does not require any pre-heating, spraying or pre-mixing. Directly mixes molasses or liquids with carbo-hydrate ingredients.

- Mixing time required is short i.e. only 6 to 8 minutes.

- Dust proof construction.

- Stuffing box arrangement provided on both side to prevent dust entering the bearings.

- Provided with sliding type discharge gate at bottom and inspection cum cleaning openings on the tip or side.

POPULAR APPLICATIONS

- Agrochemicals

- Chemicals

- Curry Masala

- Fertilizers

- Dyes

- Fish Meal

- Grains

- Intermediates

- Pesticides

- Pharmaceuticals

- Pigments

- Poultry feed

- ingredients

- Resins

- Spices

- Tobacco

The purpose of a Mixer is to blend together two or more ingredients. In a Horizontal mixer the mixing cycle is fast and dry or wet mixing can be done. A ribbon paddle type auger is mounted on the mixer haft and conveys the material from one end of the mixer to the other while it is tumbled within the mixer,Horizontal Mixer Manufacturer. Discharge opening is provided at the bottom to help in rapid discharge. These mixers are ideal where viscous material like (molasses)up to 10 % is added.

Broad Specs.

| Model |

Motor H.P |

Capacity Batch/Kgs. |

| PHM-0 |

3 |

125 |

| PHM-1 |

7. 5 |

250 |

| PHM-2 |

15 |

500 |

| PHM-3 |

20 |

1000 |

| PHM-4 |

30 |

2000 |

| PHM-5 |

40 |

4000 |

PREMIUM HORIZONTAL MIXERS