Plants

Key - Machineries

Salt Upgradation/Refinery Plants

Since the early days, man has been using common salt as food additive in the food to improve its taste and to meet the physiological requirements of the human body. During the coar se of development of the society as man needed a wide range of materials to meet its needs it became necessary to develop range chemicals that would meet these requirements. Salt became an important ingredient and raw material for manufacture of a large number of these chemicals. Salt is reported to have over 14,000 uses. Some of the major users are

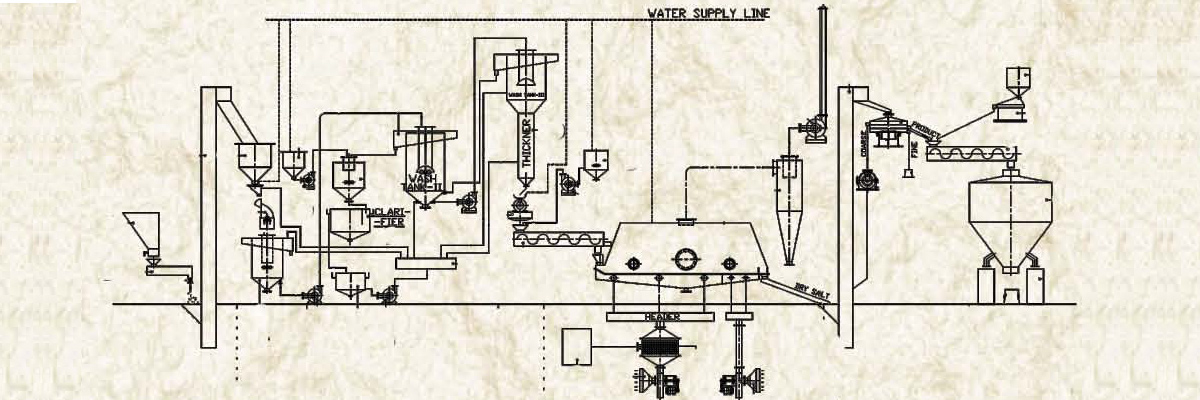

Process Of Salt Refining

(A) Raw Salt Feeding (B) Salt Washing & Milling (C) Dosing Of Additives & Coating (D) Centrifuging (E) Drying (F) Sizing & Conditioning (G) Packing (H) Brine Recycle

A) Raw Salt Is Fed To The Raw Salt Hopper From The Stockyard Or Directly Unloaded From The Dumper. Below This Hopper There Is A Feeder Arrangement. This Feeder Feeds Material To A Conveyor. This Conveyor Has Magnetic Separators At The Feed And Discharge Points To Remove Iron Pieces Li Ke Nails, Nuts And Bolts And Other Magnetic Debris. The Conveyor Discharges Raw Salt To The Feed Hopper Of The Wet Mill.

B) Wet Mill Grids And Control The Size Of The Product And Also Removes Soluble Entrapped In Grained Impurities Present In The Raw Salt Crystals. In This Process Raw Salt Is Milled With Brine To Achieve The Desired Results. Salt Slurry From The Wet Mill Falls By Gravity Into A Slurry Tank Below. In The Slurry Tank More Brine Is Added To Carry Out Primary Elutriation. Overflow Of The Slurry Tank Is Carried To The Settling Ponds. Salt Slurry Is Pumped To The Wash Tank For Main Elutriation. The Overflow Brine From Wash Tank Is Taken Into A Clarifier For Purification And To Recycle It Back Into The System.

C) Salt Slurry From The Wash Tank Is Pumped To A Thickener Wh Ere The Slurry Is Conditioned For Centrifuge. This Is A Dual Purpose Tank That Also Carries Our Secondary Elutriation As Well As Thickening Of The Salt Slurry. This Slurry Is Then Fed To The Centrifuge. Salt Cake From The Centrifuge Is Taken Up By A Screw Feeder And The Mother Liquor Is Discharged To Slurry Tank Below,

D) The Salt Cake Discharged Into The Screw Feeder Is Dosed With Iodine And Other Additive Anti Caking Agent Before It Is Carried To The Fluid Bed Dryer.

E) The Fluid Bed Dryer Is An Internationally Accepted Option For Drying Salt Cake. It Is An Integrated System Involving Two Sections For Heating And Subsequent Cooling The Product. Hot Air Is Blown With The Help Of Fan Into The Salt Bed To Achieve The Required Dryness Of Final Product. Ambient Air Is Blown Into The Cooling Section To Cool The Hot May Be Packed In Sacs And Sealed. Salt From The Outlet Of The Dryer Is Carried Up Through A Bucket Elevator For Sizing And Conditioning.

F) The Dry Salt From The Bucket Elevator Is Fed To A Gyro Screen. Oversize From The Screen Is Sent To A Dry Mill (Pin Mill) For Regrinding. The Sized Product Is Fed To The Blender For Conditioning To Make It Free Flowing Or Imparting Properties And Composition That May Be Required. Output From The Dry Mill Is Sent Back To The Screen To Avoid Any Mixing Of Oversize With The Final Product.

G) Final Product From The Blender Is Stored In A Silo. These Silos Feed The Packing Machines To Pack The Final Product To Pack The Production 1 Kg. To 50 Kg. Bulk Packing As May Be Required.

H) Clear Brine That Overflows From The Clarifier Is Taken To A Brine Tank. Sludge That Settles In The Clarifier Is Discharged Into The Settling Tank. Brine From The Brine Tank Is Pumped Into A Brine Header. This Brine Header Distributes Brine At Predetermined Rates To Various Tanks. Run-Off Brine From The Settling Pond Is Recovered And Pumped By A Transfer Pump Back Into The Process. Sludge That Settles At The Bottom Of The Pond Is Scrapped And Disposed Off To The Salt Pans Or Any Other Approved Site.

We Offer On Turn-Key Basis