General About Premium Pellet Mill

Basically the purpose of pelleting is to take a nely devised, some time dusty, unpalatable and difcult to handle feed material and by application of heat, moisture and pressure form it into larger particles. These larger particles or pellets are easier to handle, more palatable and usually result in improved feeding results when compared to mesh feed.

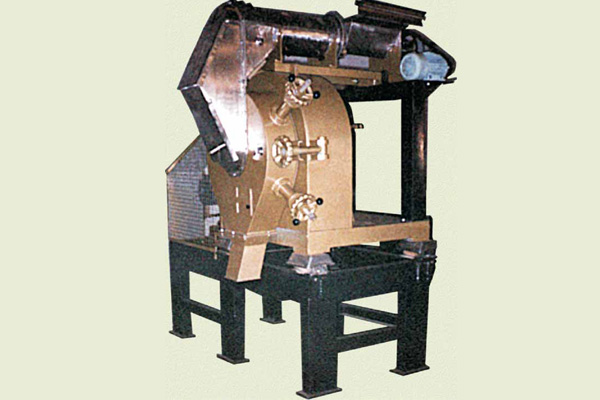

The modern type pellet mills use a ring type die turning about two in a vertical plane and consist of following component parts :-

The feeder is screw type and is equipped with a variable speed electric drive for speed control. The purpose of the feeder is to provide constant, controlled and even ow of feed to the mixing and pelletizing operation. Any variation in this ow results in poor conditioning and a variable products.

Conditioning is accomplished by the addition of controlled amounts of steam. Addition of steam supplies moisture for lubrication, liberates natural oils and in some cases results in partial geletinisation of starches.

In the pelleting unit the conditioned mash is forced through perforation in the die by roller pressure and gets compressed and forms into pellets. Adjustable knives cut pellets into desired lengths.

As the die speed is always less then the motor speed, speed reduction is provided through V-belt drive.

PREMIUM BABY PELLET MILL Model - PBPM - 025

PREMIUM JUNIOR PELLET MILLS

PREMIUM PC - 2023 - 06 MULTI CONDITIONER PELLET MILL

The Ingredients Used For Making Fish Feed, Shrimp Feed And Prawn Feed Are Fish-Meal, Shrimp Waste, De-Oiled Soya Flakes, Bone Cum Meat Meal Ete. These Ingredient Required Cooking /Gelatising Before Pelletizing. Premium Multi Conditioner Pellet Mills Have More Then One Conditioner Besides Screw Feeder. The Size And No. Of Conditioner Will Depend Upon Type Of Aqua Feed To Be Produced And Type Ofi Ngredients Used. Direct Steam Is Injected Into Mixed Feed. The Higher Moisture At Higher Temperature And Higher Retention Time Will Improve Gelatisation All Conditioners Are Having Steam Jackets And Are Made Of S.S. And Have Variable Speed. The Multi Conditioner Pellet Mill Are Used For Aqua Feed Manufacture In Various Capacities And Size Of Hole Of Pellet Die Ring Is From 1.8 Mm Ø To 3.00 Mm Ø

PREMIUM PELLET MILLPELLET MILL FOR UNCONVENTIONAL APPLICATION

To Convert Fiberous Agricultural Waste Like Straws Into Pellets For Ruminients, To Convert Wood Flakes / Powder In Wood Pellets And To Convert Coal / Wood Waste Into Pellets Of 12mmØ And Above Premium Pellet Mills Are Manufactured In Different Capacities With Appropriate Die Ring / Rollers And Drive Mechanism To Unconventional Pplication For Rumanians And Unconventional Energy Source The Size / Model Is Selected Based Upon Capacity

PREMIUM SENIOR PELLET MILLS

Nish, Design Of Rolls And Die-Holder Gives Extra Life To Pellet Mill.Premium Senior Pellet Mills Are Available In Three Seizes I.E. Senior, Super Senior And Super-Max Senior And Are Capable Of Producing 5 Mt/Hr, 7.5 Mt/Hr And 10 Mt/Hr Pellet Of 8 M.M Ø. Smaller The Dia Of Pellet Less Will Be Out Put. Ron Particles All Contact Parks Like Screw Feeder, Conditioner, Down Spout Are Made Out Of S.S., To Provide Protection Against Corrosion. Doors, Windows And Hinged Covers Are Provided To Facilitate Cleaning And Have Easy Accessibility To Die-Ring And Holders.Correct Selection Of All Bearings, Dynamic Balancing Of V-Pulleys, Selection Of V-Belts,No Of V-Grooves, Safety Shear Pins, Size Of Chambers, Location Of Knife Cutters, Size Of Holes Its Taper And Premium Senior Pellet Mills Are Robust In Construction And Are Designed For Continuous Production In Automatic Feed Plants. They Are Feed And Have Steam Connection The Pellet Mill Have Three Major Sections. (1) Feeder (2) Conditioning Chamber (3) Pelleting Device Besides Speed Reduction, Prime Mover And Base Frame. The Capacity Of Pellet Mill Is Designed By Size Die-Ring I.E. Inner Dia, Width And Size Of Hole. The Design Of Pellet Mills Gives Maximum Out Put Per Unit Consumption Of Electric Power Safely And Protection Against Entrance O

PREMIUM SENIOR & SUPER SENIOR PELLET MILLS

PREMIUM SUPER MAX SENIOR PELLET MILLS